Systems for process machinery

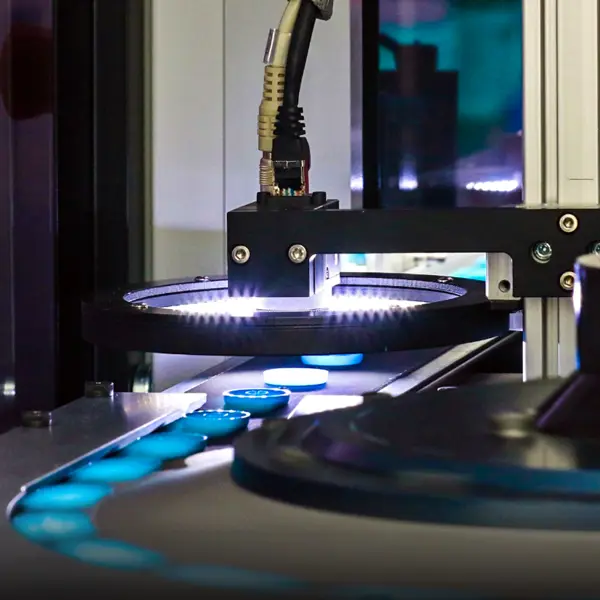

Systems integrated into production machines enable inline control of incoming parts and finished products at any production speed. In addition to inspection tasks, they can detect and communicate the orientation of components to assembly equipment with “optical” adjustment.

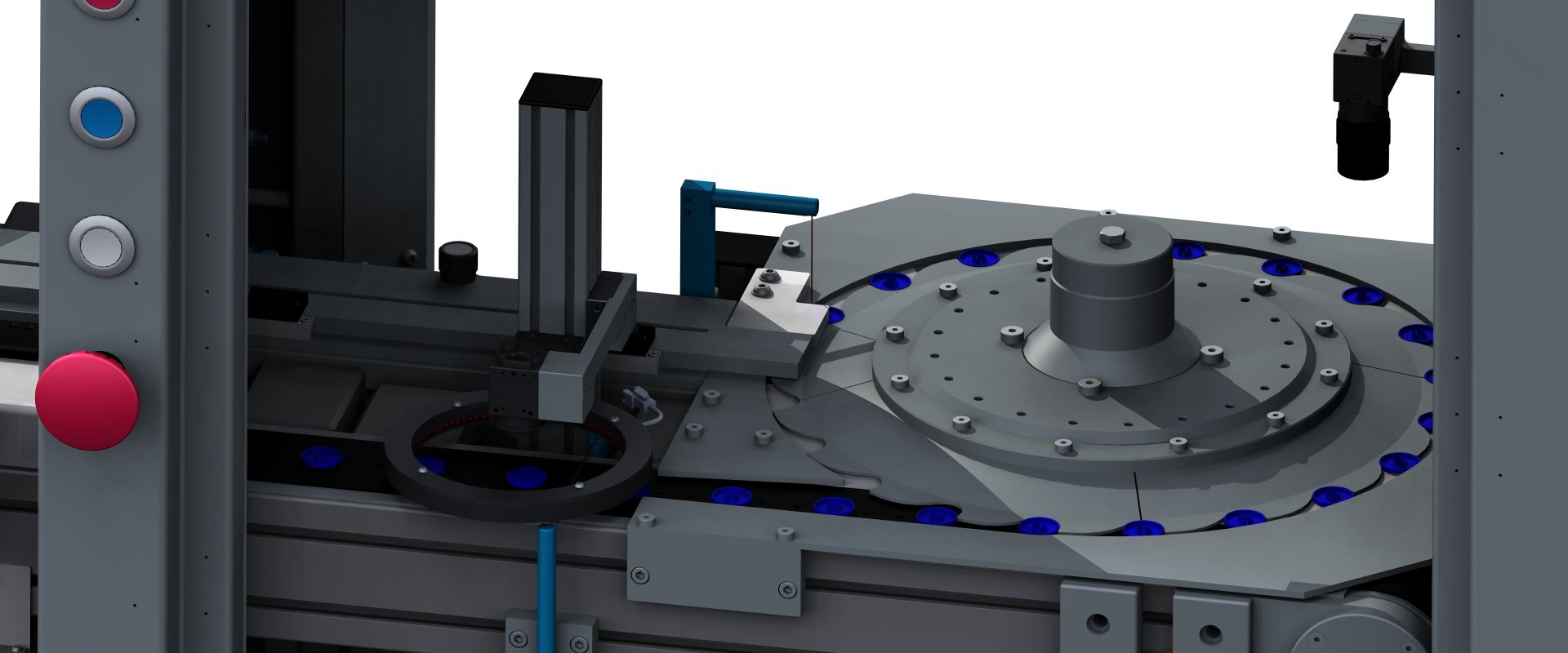

A single partner for complete inspection lines

With proven solutions made by our machines division, we provide all the components necessary to present, inspect and package molded plastic closures. Our machines work together in an integrated factory network and can communicate with Manufacturing Execution Systems (MES) in line with the requirements of Industry 4.0.

State of the art inspection technologies

A variety of cutting-edge vision technologies ensures the best inspection possible.

Ready for tethered caps

With market-leading artificial intelligence tools, our systems offer the complete inspection of tethered caps without requiring any prior orientation.

With our PROINSPECT software, new inspection tasks can easily be introduced without writing code. Changes can be validated on classified images and put online without stopping production.

Easy to use, with comprehensive information

PROINSPECT offers an optimized experience to every user. From the simplicity and ease of use for production operators to installation engineers' full range of functions.